The servo motor follows the position change in the knob and so we can rotate the servo in clockwise or counterclockwise by rotating the wiper of the potentiometer.

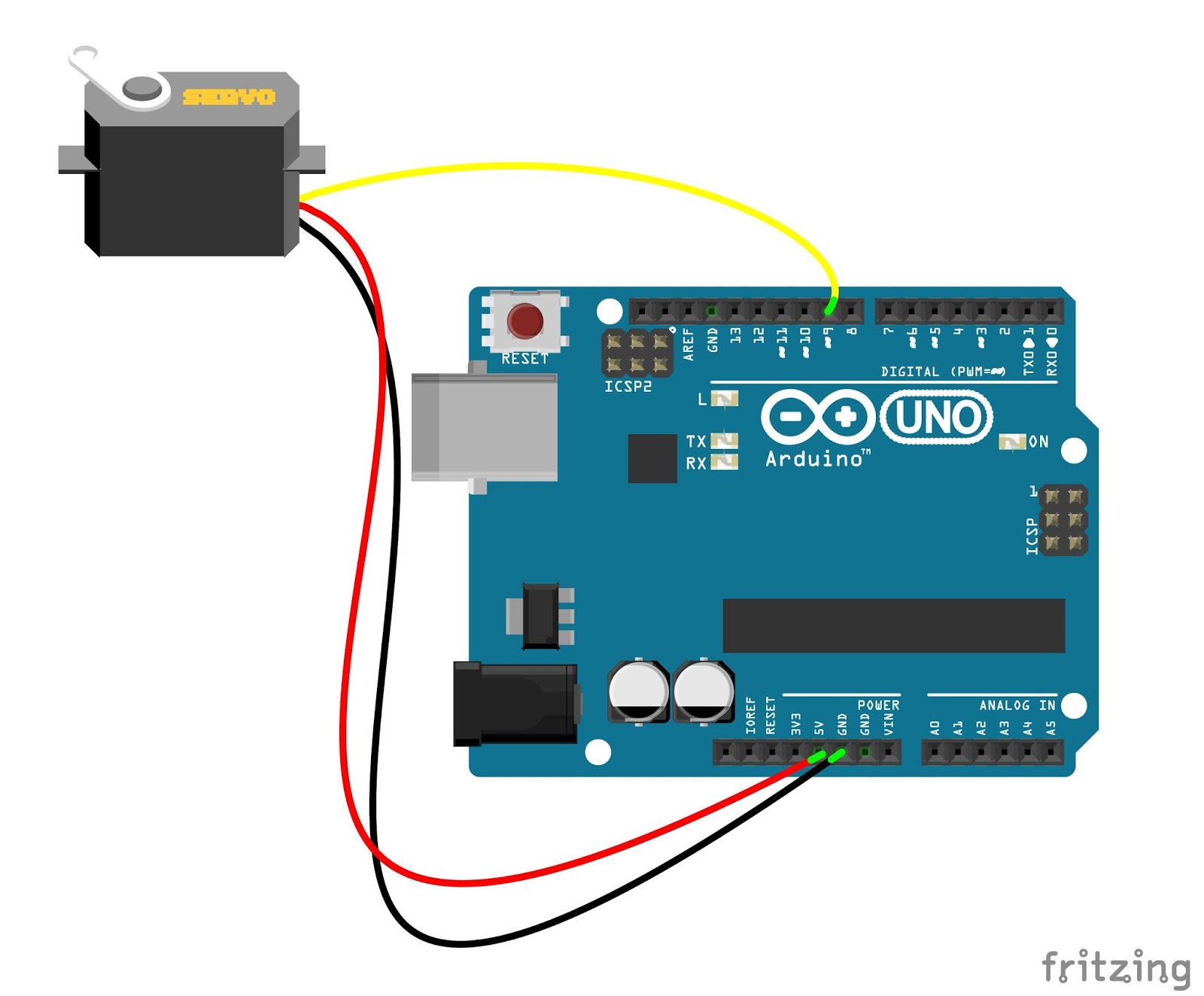

In this arrangement, the angles of the servo can be controlled by turning a knob and the current position of the servo will be displayed on the LCD. Thus, every position change in the potentiometer will make the corresponding angular position change in the servo motor. And will turn towards 0° and 180° when rotating the knob towards GND terminal T2 and 5V terminal T1 respectively. That is when the knob is at centre position the servo arm will be at 90°. Thus the angle of servo proportionally increments and decrements with the increase and decrease in input value. In the program, we map the values between 0 – 1023 to 0° – 180°. So the analog input values for the range 0 to 5 volt is converted into corresponding decimal values from 0 to 1023. The arduino uno has a 10-bit analog to digital converter. The terminal(T1) of the potentiometer is connected to supply voltage and the other terminal(T2) to the ground.īy turning the potentiometer, the input voltage varies in the range of 0 to 5V. The wiper pin of the potentiometer is connected to analog input of the arduino. The servo moves clockwise or counterclockwise (0° – 180°) with the corresponding angular position of the potentiometer. At every instant, the servo arm follows the position of the Knob. Here we are controlling the angular position of a servo motor using a potentiometer. It connects to the ground pin of the Arduino. The ground wire typically has black or brown colour. And connect the supply terminal of the servo (+V) to the +Ve terminal of the external supply. Because the power at the remaining pins would be interrupted during its operation.įor external powering, connect the ground of the arduino commonly with the -ve terminal of the external power supply. So, for multiple servos or while using servos along with other pins, it is better to power the servo motor separately with an external supply. The Servo motor requires a considerable amount of power, especially for high power servos. The power wire mostly has a red colour, which connects to the 5V pin of the Arduino. Servo motor interfacing with Arduino Power The servo motors are interfaced with the Arduino through a standard three-wire connection. Thus the pulse width between 1ms and 2ms obtains a corresponding position between 0° to 180° angles respectively. For a standard servo, 1ms positive pulse maintains a 0° and a maximum of the 2ms positive pulse will have a position of 180°. That is the duration of the positive pulse in a 20ms total pulse width determines the servo shaft position. The width of each pulse directs the servo to turn the shaft to the corresponding angular positions. The servo motor expects a control pulse at every 20 milliseconds (ms). The input pulse train at the control signal will turn the rotor to the desired position. The angular positions of a servo motor are controlled by the pulse width modulation(PWM).

0 kommentar(er)

0 kommentar(er)